Published: 20 February 2015

Category: Manufacturer News

Our INFORM@X® instrumentation cables keep everything in tune.

Our INFORM@X® instrumentation cables keep everything in tune.

In today’s fast paced society it’s becoming more and more vital that interconnections between electrical instruments, computers and control equipment keep the beat. That’s why our product family of instrumentation cables, INFORM@X®, offer optimal protection against electrical noise and all the integrity measures you may need to conduct the tempo.

INSTRUMENTATION

INFORM@X® P50 – P56

Application

The INFORM@X® P50 – 56 range of cables are designed for the interconnection of electrical instruments, monitoring and control equipment within industrial systems and processing plants.

Typical uses include

Supervisory Control And Data Acquisition (SCADA) systems, electrical sensing devices, field bus RS 485 and RS 422 data links, control cabinets to supervisory consoles, electrical measuring devices, Resistance Temperature Detectors (RTD) and many other supervisory applications.

Typical wiring systems will use multi-pair cables to connect control room equipment to panels in field junction boxes. Single pair cables are used to connect junction boxes to field devices.

INFORM@X P50 – 56 cables are suitable for use where it is necessary to provide:

- Protection from Interference to the transmission signal from other electrical circuits.

- Prevention from physical damage to the cable (achieved by screens and steel wire armour, where applicable).

- Intrinsically safe cables (coloured blue).

Approvals

AS/CA S008

These cables are not to be regarded as power cables for mains power supplies.

Behaviour in flame and fire:

Flame Propagation to AS/NZS 1660.5.6

Temperature range

Minimum installation temperature: 0 °C

Maximum operating temperature: +75 °C

Minimum operating temperature: -25 °C

Minimum bending radius

Installed cables: refer to data tables.

Resistance to

Chemical exposure: Occasional

Mechanical impact: Light

Water exposure: Spray

Solar radiation and weather exposure: Occasional

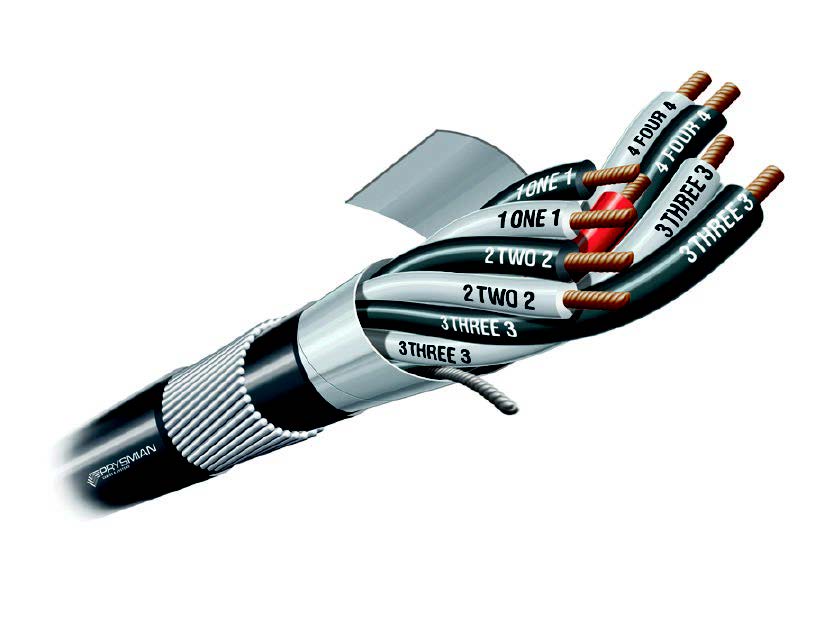

Cable design

Conductor:

Plain copper wire

P50/P53 – 0.5 mm2 (7/0.3 mm), 20 AWG

P51/P55/P56 – 1.5 mm2 (7/0.5 mm), 16 AWG

Insulation:

V-90-HT PVC

Construction:

P50/P55 - Multi-pair; black and white numbered cores

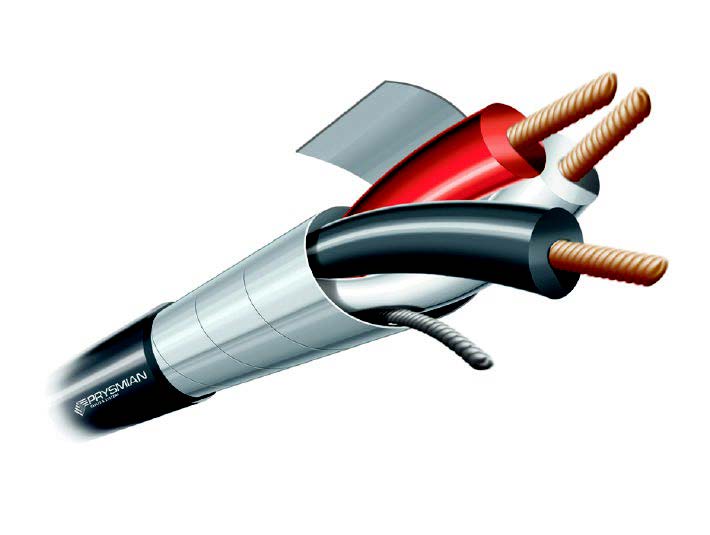

P53/P56 - Multi-triple; black, white & red numbered cores

P51 - Single pair or triple, colours as above

Sheath:

V90-HT PVC

Colours: Black, Blue on request.

Screen:

Aluminium/Polyester tape with a 7/0.2 mm tinned copper drain wire.

Armour (optional):

Galvanised mild steel wire.

(Add SWA to the product code).

Communication wire (optional):

A 7/0.25 mm central communication wire.

All sizes and values without tolerances are reference values. Specifications are for product as supplied by Prysmian Group: any modification or alteration afterwards of product may give different result. The information contained within this document must not be copied, reprinted or reproduced in any form, either wholly or in part, without the written consent of Prysmian Group.

The information is believed to be correct at the time of issue. Prysmian Group reserves the right to amend this specification without prior notice. This specification is not contractually valid unless specifically authorised by Prysmian Group.

General Information

Element

An element consists of a pair (or triple) formed by twisting the wires together. Elements are twisted with different twist lengths to reduce interference between them.

Cable core

The cable core is formed by assembling the required number of wires or elements together.

Screened element (ES)

The twisted element is wrapped with aluminium/polyester laminate as a tape with the bare tinned copper wire laid in contact with the aluminium side of the tape. A further layer of polyester tape is applied over the core.

Screened core (CS)

The aluminium/polyester laminate is applied as a screen over the core with the bare tinned copper drain wire laid in contact with the aluminium side of the tape.

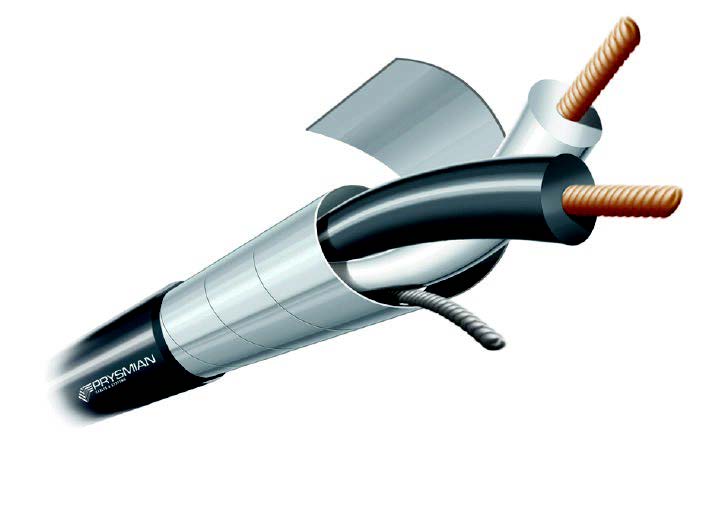

Armour (SWA)

A further protective covering can be provided by the application of galvanised steel wires and a PVC oversheath.

Sheath

The wrapped core is sheathed with PVC.