Strict regulations for lighting food handling and processing areas make luminaire selection a critical element of facility design and functionality. Factors such as contamination and sanitation dictate parameters around mechanical construction while AS/NZS 1680.2.4 sets out provisions for a “visual environment conducive to the safe and efficient performance of tasks associated with industrial activities and processes".

To this end, Sammode Lighting Australasia is a preferred supplier in many food production applications based on performance, quality and four other design advantages each luminaire provides to end users. They include:

| Robustness For Sammode, long-lasting mechanical resilience is essential. Longevity, durability and the endurance of our equipment are proof of this. By using high quality construction materials, the fixture bodies will in most cases out live the 50,000 hour LED source. All fixtures also feature a high impact rating of IK10. |

| Imperviousness IP66 / IP68 / IP69K rating means the fixture excludes all dust and high pressure water. The IP69K test uses a high pressure water gun with 80°C hot water. This imperviousness protects the internal components against performance degradation from dust and moisture to achieve a very long and reliable service life. |

| Resistance The POME Diffuser is a co-extrusion of polycarbonate and acrylic which provides an increased resistance to oils and UV light. Typically polycarbonate absorbs oil and becomes embrittled resulting in cracking and breaking around its fasteners and corners; it also "yellows" over time when exposed to UV light. Sammode’s POME Diffuser provides resistance against both of these issues. |

| Maintainability Sammode luminaires are designed for simple and easy disassembly on site allowing individual components to be removed and maintained as needed. This ensures the asset owner can maximise the life of their investment by maintaining and replacing the LED light sources and other components with minimal interruption to productivity. |

LED Food & Beverage Industry Solutions from Sammode

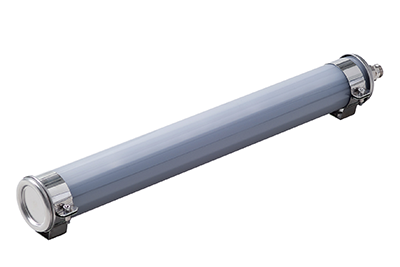

Sammode’s range of high quality luminaires designed for the food and beverage industry include:

|

Doppler 70 24DC |

Doppler 70 230V |

Pascal |

Solution | Process & machine lighting | Process & machine lighting | Food processing & storage |

Benefit | Excellent mechanical & vibration resistance | Excellent mechanical & vibration resistance | Efficient general lighting |

Operating Temp. | -30°C to +60°C | -20°C to +40°C | -20°C to +35°C |

Colour Temp. | 4,000K | 4,000K | 4,000K (3,000K available) |

IP Rating | IP66, IP68 & IP69K | IP66, IP68 & IP69K | IP66, IP68 & IP69K |

Electrical Protection | Class III | Class II | Class I |

Light Source Life | 50,000 hours | 50,000 hours | 50,000 hours |

More Info |

FLUORESCENT SOLUTIONS

In need of a fluorescent solution for food and beverage production or processing?

Sammode’s Einstein Agro is a very long life and efficient fluorescent option featuring very long life fluorescent tubes providing 75,000 hour life.

Sammode’s Einstein Agro is a very long life and efficient fluorescent option featuring very long life fluorescent tubes providing 75,000 hour life.

Discover more about this solution here.