Published: 26 June 2014

Category: Technical Articles

The lighting industry, like many industries, is full of acronyms, abbreviations and buzz words that can be latched onto to promote products...

LED is probably the most prominent and relevant at the moment. Everything you buy that uses a light emitting diode has ‘with super bright LED light’ or ‘energy saving LED light included’ written on the box. The fact that the light source is an LED is irrelevant. What you want to know is how much energy it consumes and how much light it emits.

I find that these shorts cuts and buzz words are used to often and often make reading through literature difficult. So, for the rest of this article I will highlight a number of terms used in marketing literature and datasheets that maybe unknown to you or detract from what you really need to know about the product you’re reviewing or installing.

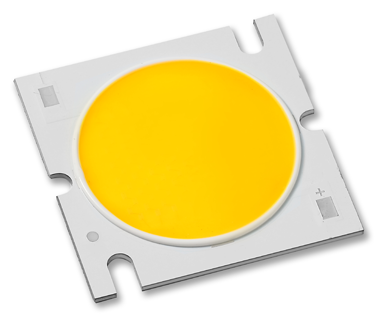

COB

I also thought this was the world recognised acronym for ‘close of business’, but apparently not. It now means ‘Chip on Board’. A ‘COB’ is a type of LED that uses lots of small low power LED chips to form the light source, opposed to using a single, small, high powered LED chip. This results in a larger area for the light source and helps to reduce glare. It can also improve heat dissipation, which in turn improves the lifetime of the light source. However, rely on the manufacturers stated lifetime for that particular product to compare against any other product, rather than just assuming ‘COB’ means long and reliable lifetime. There are many other parts of the luminaire that can fail before the LED chip!

BridgeLux

BridgeLux is simply a brand of LED chip. This is an American company formed to innovate in the manufacture of LEDs to bring high power, cost effective LED chips to the market. So really, this does mean much at all if you’re buying a light fixture that uses these chips. The exact fixture performance characteristics for efficiency, rated lifetime, glare etc are what are important. The light fitting is as good as its weakest point. The use of the most efficient or reliable LED chip is irrelevant if it’s powered by a low quality driver.

CREE LED or LUMILEDS LED

Again, more examples of LED chip manufacturers’ names. Some light fitting manufacturers feel it necessary to state where the chips come from. It does give piece of mind that the LED chip is of good quality, but as mentioned above, this gives no guarantee on the rest of the fitting.

OLED

‘Organic Light Emitting Diode’. Organic LEDs are different from standard LEDs. An OLED is a sheet of material that emits light when an electric current passes through it. They can be used in televisions and hand held devices in replacement of an LCD (Liquid Crystal Display….there’s another!). Advances in technology are now seeing high powered, white light OLEDs being available on the market that can be used for lighting applications. The large area of an OLED emits a very comfortable light, opposed to small LED chips that can be very glary, so are very suitable for interior lighting. An OLED panel can also be flexible, so the applications are limitless. Although OLEDs are already very efficient, they are relatively expensive. However, it is predicted that their efficiency will improve considerably and costs will reduce. In the future it is likely that linear fluorescent will start to be replaced with OLED luminaires and panels.

ECG

‘Electronic Control Gear’. This is pretty self-explanatory. Electronic control gear can be used to power high intensity discharge (HID) lamps or LED. Although, HID electronic control gear can not be used on LED and vice versa. Electronic control gear is becoming standard in many applications because they use less power and generally run at higher power factors than traditional ballasts.

CLO

‘Constant Lumen Output’. Constant lumen output is a technique by which the power supplied to the light source increases over time to counter act the degradation of the light source which would usually result in the light output reducing. All light sources reduce in efficiency over time and traditionally you allow for this degradation in your lighting design calculation by means of a lumen depreciation factor. Using constant lumen output means your design lumen maintenance figure is 100%.

Using constant lumen output is a very effective way in which to save energy without having to dim the light level at certain times of day. There is some debate on how dimming a HID lamp affects expected life, but the efficiency of the lamp generally does decrease as you dim the light output. LED, on the other hand, acts conversely to this. The efficiency of an LED chip increases when it is dimmed. The lifetime of the chip is also extended the more it is dimmed, so opting to use constant lumen output with an LED installation offers many benefits.

LXX e.g. L70

‘LXX’ is an abbreviation that refers to a certain percentage of the initial light output of an LED fixture. For example, 80% of initial output would be written as L80. This abbreviation is commonly used in quoting the predicted amount of time it takes for the product’s light output to reduce to this initial light output percentage. A product may be quoted to having L70 @ 50,000hrs. So after 50,000hours the light output is predicted to be at 70%. Do note that this is a prediction, and can vary considerably depending on what the ambient temperature was in the lab and what is likely to be experienced in application.

The prediction is most commonly carried out in accordance with standard TM21…..

TM21

‘TM21’ is a North American standard that has been widely accepted around the globe as the standard for predicting how the light output of an LED chip or LED luminaire will degrade over time. The prediction is based on a minimum test duration of 6000hrs. The data from the 6000hour test is extrapolated out using a defined algorithm from TM21 to establish where the LXX values will fall for that particular light source when operated at a defined temperature and current.

The test data collected over the 6000hours is carried out to LM80 standard….

LM80

This is another North American standard that has been widely accepted by the lighting industry and it defines how to measure the lumen depreciation of a solid state light source. It has been created to establish a common test method between laboratories to facilitate the easy and accurate comparison of test data from different laboratories. So, ultimately, it makes our lives much easier.

I hope this has been helpful.